Outdoor Cooling Tower, Indoor Pump-Tank & Heat Transfer Skid

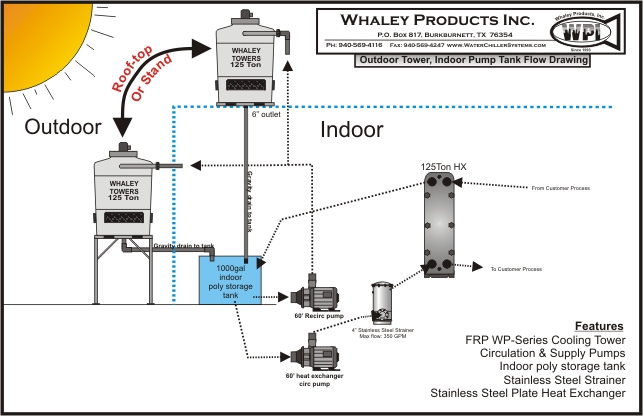

WPI’s clients are located all around the world. This means that we have designed our systems to operate in every variation of annual ambient amospheric conditions. The CLIO-Series closed loop cooling tower systems were created to serve these extreme weather conditions. An outdoor cooling tower installed on an elevated stand or on the roof accompanied by an indoor sump storage tank, pumps, strainer filtration, and heat exchanger is the solution.

|

Model

|

Tower Tons / KW

|

Flow: GPM

|

HX Type

|

PUMP

|

Strainer In/Out

|

Strainer Max Flow

|

| CLIO650-10 |

10 Ton/44KW

|

30 GPM

|

PHX

|

1.0 HP, #11, 4.88″

|

2″ NPT Bottom

|

100 gpm

|

| CLIO650-15 |

15 Ton/66KW

|

45 GPM

|

PHX

|

1.5 HP , #126, 5.25″

|

2″ NPT Bottom

|

100 gpm

|

| CLIO850-20 |

20 Ton/88KW

|

60 GPM

|

PHX

|

2.0 HP, # 16, 4.75″

|

2″ NPT Bottom

|

100 gpm

|

| CLIO850-25 |

25 Ton/110KW

|

75 GPM

|

PHX

|

2.0 HP, #16, 4.88″

|

2″ NPT Bottom

|

100 gpm

|

| CLIO1250-30 |

30 Ton/132KW

|

90 GPM

|

PHX

|

3.0 HP, #17, 4.75″

|

2″ NPT Bottom

|

100 gpm

|

| CLIO1250-40 |

40 Ton/176KW

|

120 GPM

|

PHX

|

3.0 HP, #17, 4.75″

|

3″ NPT Bottom

|

200 gpm

|

| CLIO1550-50 |

50 Ton/220KW

|

150 GPM

|

PFHX

|

5.0 HP, #17, 5.25″

|

3″ NPT Bottom

|

200 gpm

|

| CLIO1550-75 |

75 Ton/330KW

|

225 GPM

|

PFHX

|

7.5 HP, #15, 4.88″

|

4″ flange side

|

350 gpm

|

| CLIO1850-100 |

100 Ton/440KW

|

300 GPM

|

PFHX

|

10 HP, #15, 5.25″

|

4″ flange side

|

350 gpm

|

| CLIO1850-125 |

125 Ton/550KW

|

375 GPM

|

PFHX

|

10 HP, #56F, 5.00″

|

4″ flange side

|

350 gpm

|

| CLIO2-1850-200 |

200 Ton/880KW

|

600 GPM

|

PFHX

|

20 HP, #57, 5.50″

|

6″ flange side

|

750 gpm

|

| CLIO2-1850-250 |

250 Ton/1100KW

|

750 GPM

|

PFHX

|

20 HP, #57, 5.50″

|

6″ flange side

|

750 gpm

|

| CLIO3-1850-300 |

300 Ton/1320KW

|

900 GPM

|

PFHX

|

20 HP, #96, 8.90″

|

8″ flange side

|

1300 gpm

|

| CLIO3-1850-375 |

375 Ton/1650KW

|

1125 GPM

|

PFHX

|

25 HP, #96, 9.38″

|

8″ flange side

|

1300 gpm

|

| CLIO4-1850-400 |

400 Ton/1760KW

|

1200 GPM

|

PFHX

|

25 HP, #96, 9.38″

|

8″ flange side

|

1300 gpm

|

| CLIO4-1850-500 |

500 Ton/2200KW

|

1500 GPM

|

PFHX

|

30 HP, #96, 10.0″

|

10″ flange side

|

2000 gpm

|

Energy Savings Benefits with the CLIO-Series Tower System:

Freeze Protection: During the cold months when your cooling tower is not needed, the tower water drains into the indoor storage tank. This elimintes the possibility of freezing. With this type of indoor/outdoor closed circuit system, you eliminate the need for an outdoor tower basin heater.

Indoor Climate Controlled Storage Tank:With the storage tank indoor, you will use less energy to cool the water in the hot season. Remember less consumption of energy equals more positive “going-green” company.

The FRP tower composite material: Fiberglass Reinforced Polyester….Heat resistant, UV resistant, fire resistant, marine grade material used in boats.

Direct Drive Fan Motors: No belts or gear-drive boxes, just a simple energy efficient direct drive fan motor.

Axial Fan Blades:

Manufactured with non-corrosive aluminum and plastic materials to ensure long life. The axial fan blades are aerodynamically more efficient. The position on top of the tower above the fill pack and distribution system, coupled with the aerodynamically efficient shape of the Whaley Cooling Towers, ensure superior performance continuously

Lower your Maintenance Costs

Rust Issues: Other cooling tower companies offer what our contractors like to call “Rust-Balls”. These are galvanized steel cooling towers that are prone to rust if they are not perfectly meticulously maintained according to the maintenance manual. We thought we would share some pictures of some rust balls. Feel free to click on them to enlarge. Before considering installing any cooling tower system, we recommend you call several local mechanical contractors in your area and ask them their experiences with rust problems associated with galvanized towers.

|

|

|

Whaley Towers have a life expectancy of 20+ years.

How does WPI accomplish this? Very simple.

WP Series Cooling Tower Features

Construction material details:

Non-corrosive FRP(Fiberglass Reinforced Polyester) marine grade resins

Surface layer containing pigmented gel coat

Ultraviolet (UV) inhibitor included as an additive to the composite matrix.

Accu-Pac cross fluted fill pack:

Improves water distribution by splitting water stream 8 times in a 12” vertical path as it descends through the fill pack

Constructed entirely of CTI (Cooling Tower Institute) Standard 136 PVC

Accu-Pac counterflow cellular drift eliminators

High surface area provides maximum performance at minimum pressure drop

Constructed entirely of CTI (Cooling Tower Institute) Standard 136 PVC

Cellular Inlet Louvers installed:

Improve air flow into cooling tower

Prevent debris from entering

Eliminate water splash-out that can cause icing, water treatment chemical loss

Restricts amount of sunlight into cooling tower impeding algae growth

Reduce noise from tower

Improve tower’s appearance

Constructed entirely of CTI (Cooling Tower Institute) Standard 136 PVC

Lightweight ABS plastic non-clogging Dek-Spray nozzles

serviceable at temperatures up to 180F/82C

Results in less system weight & piping cost

Steel Tower platform with fork slots

4″ C-Channel

Sheered sheet metal cover with cut-out for bottom tower drain

Painted with gray Macropoxy 646 Fast Cure Epoxy (high solids, high build, polyamide epoxy designed to protect steel and concrete in industrial exposures)

Side or bottom outlet drain

Location and size of outlet fitting determined according to your requirements

Other Features

Schedule 80 distribution header |

PVC inlet flange |

½” automatic water makeup  |

Stainless steel hardware |

Glossy white color |

Direct drive fan motors |

Axial fan blades |